BRAWOLINER HELPS KEEP COLLEGE BUILDINGS DAMP FREE

- Martyn Kelly

- Mar 23, 2020

- 5 min read

Marlborough College in Wiltshire, UK is a highly respected independent school for day and boarding pupils. The College was established in 1843 by a group of Church of England clergymen. Today the College is a fully co-educational establishment catering for about 930 pupils with the great majority (98%) being boarders. The Duchess of Cambridge is a former pupil.

Of the full boarding schools across the country, Marlborough was recently ranked 4th with an 82% acceptance rate for pupils to the UK’s top 30 universities, a rating bettered only by Westminster School, St Paul’s School and Winchester College.

As with all buildings that have been in use for some considerable time, Marlborough College’s infrastructure is constantly reviewed and repaired or upgraded as necessary.

Recently part of this ongoing process there was a need for the renovation of a significant part of the College’s North Block including the building’s rainwater drainage system. The system comprises very old and ornate cast iron rain water downpipes that in places are hidden within the fabric of the wall and which take rainwater from the roof to ground level drains. In places these downpipes were leaking causing damp problems within the building. Given their design, location and accessibility they would have been very difficult to replace in keeping with the original building construction so an alternative to full replacement was sought.

RENOVATION OPTION

In looking at the options available with which to bring the rainwater downpipes back up to the standard required, Mark Norton from Architects Gray, Baynes & Shew of Oxford (www.gbsarchitects.co.uk) contacted CJ Kelly Associates with a view to using lining techniques as the alternative to full replacement. As part of this consultation, John Kelly, Senior Partner at CJ Kelly Associates suggested that the project co-ordinator Mark Norton of Gray, Baynes & Shew contact S&D Services of Chard, Somerset, UK, a specialist in drainage repairs and lining. This suggestion was taken up by Mark who then liaised with the College’s main works contractor, construction specialist Stepnell.

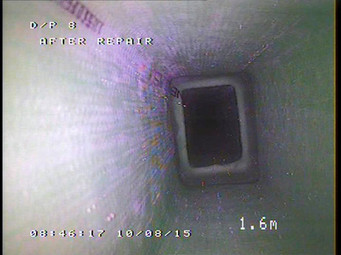

After full investigations at the College a programme of work was established to install CIPP liners to seal some 17 rainwater downpipes. The liners would also help to reduce the potential for any further deterioration in the rainwater handling system.

Given the age of the property it was no surprise to S&D Services’ managing director Steve Sampson and his fellow Director Stephen Wadham who ran the project on site, that there were a few problems regarding the downpipes. The main problem highlighted by the CCTV inspection of the pipes was that over the lengths of these they not only changed shape and size internally but that were also other imperfections within the pipes, some of which had been generated by previous attempts to repair them.

Having established the scope of the problem, Steve Sampson and John Kelly met on site to discuss potential liner options. After looking at the CCTV and after various discussions John advised using a lining system that comprised the DN 100 to 150 Brawoliner 3D liner material in association with a Brawo 1 resin.

This liner was selected because it is designed to handle cross-sectional changes within a pipe being lined and so could easily accommodate the many and frequent changes of shape, size and bends that had been highlighted in the survey. The selected resin also cures quickly when heat is applied with steam and or hot water thereby minimising the timeframe for each lining operation.

The proposed lining technique was presented to Mark Norton of Gray, Baynes & Shew, the main contractor and the client and approval was received to commence the works. Once this approval had been given, S&D Services ordered the materials from CJ Kelly and the delivery was onsite within 24 hours. Steve Sampson commented: “As always when we find ourselves working with John and his team we received an excellent and speedy service and they are always available with back-up should we need it.”

LINING WORKS

The Marlborough College site had very limited access and this meant that everything that was required to complete the lining works had to be extremely portable. Most of the work was undertaken from a scaffolding that had been previously erected for other building works by the main contractor. For some of the liner installations, however, the work was undertaken from a scissor lift.

These unusual circumstances posed significant challenges for S&D but careful consideration of the situation led to the development of rather unusual but safe methods of working which was a paramount focus given that the lining team would be working at height.

The operation was also time limited because it required a footpath closure to maintain safety for passers-by and further to this, access for the lining team to site was only available between 07.30 and 17.00 on lining days, a limit that had to be strictly adhered to because of client demands. Even given these restrictions, the use of the Brawoliner system with the fast cure Brawo 1 resin enabled the S&D team to install up to three liners a day.

To minimise the impact of the works on the functioning of the College, the work was undertaken in two parts. The first part comprising the bulk of the lining work was undertaken over the 2015 long summer holiday break. The remainder of the linings were completed during the half term break in October 2015.

Whilst individual liners presented different challenges due to the variation in sizes and shapes over their lengths the lining process was pretty much the same for each installation. Prior to the start of the works all the downpipes were surveyed and measured so that as each to be lined there was no need to take measurements on the day.

To line each downpipe first a 90o bend was added to the bottom of the pipe. The bend was then blocked to prevent the liner from expanding outside of the confines of the pipe being lined. This allowed the resin impregnated liner that had been previously prepared to be inverted into the pipe with compressed air up to the stop in the bend. The liner was kept constantly under pressure with air and forced back to form, shape and with the resin side out to adhere to the contours of the downpipes. This was then heated with a small volume of very hot water which was sufficient to cure the material. The fast cure resin meant that each cure took no more than 2 hours. Once curing was completed the bend at the base of the down pipe was removed and the liner was cut back to fit flush with the downpipe end.

Whilst the curing process was being completed on one liner, the liner material for the next installation was being prepared and this was impregnated just ahead of its installation once the lining installation equipment had been moved from the last position.

Steve Sampson said of the project: “Mark Norton of Gray, Baynes & Shew, who ultimately acted as project manager for this scheme, was instrumental in making this task work by undertaking the preliminary enquiries with both John Kelly and ourselves and then liaising with Stepnell.”

Stephen Wadham, who ran the project for S&D Service on site, said: “The Stepnell team were easy to work with. Before starting work, we liaised closely with them to ensure that Stepnell’s exacting safety standards and site rules were complied with in every respect. By keeping our clients informed in advance of where we wanted to work and of any problems we were encountering they were able to arrange access and make preparations for us in advance ensuring there were no hold ups. This was crucial to enabling us to finish on time and in budget.”

John Kelly of CJ Kelly Associates said: “This was an excellent situation for our Brawoliner 3D system as it met all the demands of the site and provided a solution that saved time, money and the need to fully replace the rainwater drainage system at Marlborough College. This is precisely the sort of situation this liner was designed to meet. It was also a pleasure to work with a set of contracting teams that could work closely together so well to achieve the required solution.”

Commentaires